Dual-line system

Slurry tanker and trailer

RDS/trailer dual-line system

for all slurry tankers and trailers

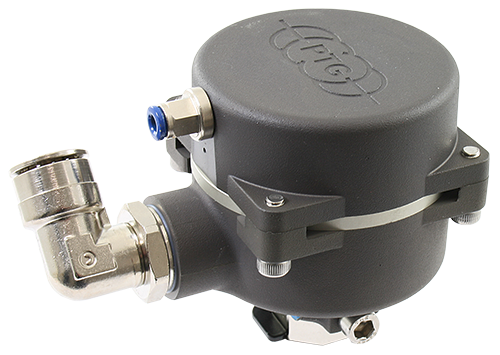

- Safety against pressure loss in the tire thanks to automatically switching PTG 2L speed wheel valve

- Control line opens wheel valve only for tire pressure adjustment/measurement

- Depressurized lines when the tire pressure control system is inactive or switched off

- Maintenance-free

- Operation of the system via digital or ISOBUS control

- Precision control in the pressure range 1 to 4 bar (factory setting, 0.8 to 6 bar on request)

- No external pipes and air ducting through the pre-drilled trailer axle

- Long service life of the rotating unions

- Can be combined with various PTG air supply systems

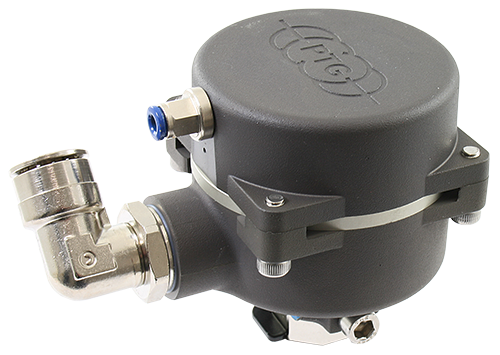

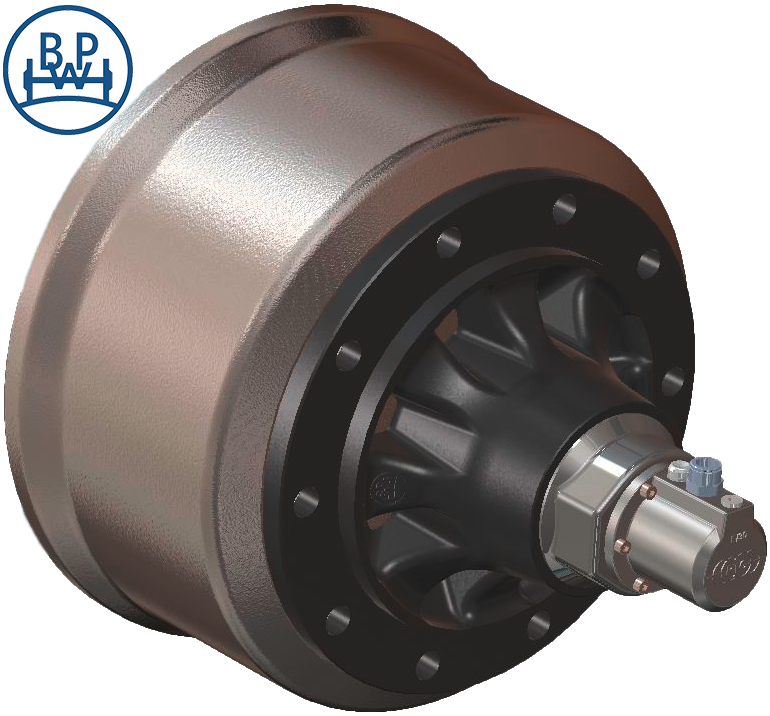

RDS rotary feedthrough for drilled BPW axles

- Tested and approved by BPW

- Patented solution for agricultural axles from BPW Rotating union bolted with grease cap – no ingress of dust and water possible

- Integrated pressure equalization element – no air ingress into the wheel hub

- Optimum protection of axle beam and axle bearing against corrosion

- High air permeability

RDS rotary feed-through for drilled ADR axes

- Tested and approved by ADR

- Patented solution for agricultural axles from ADR Rotary feedthrough bolted with grease cap – no ingress of dust and water possible

- Integrated pressure equalization element – no air ingress into the wheel hub

- Optimum protection of axle beam and axle bearing against corrosion

- High air permeability

PTG universal rotary union

For drilled trailer axles such as FAD, Colaert Essieux, etc.

Singl-line system

Slurry tanker and trailer with drilled axles

RDS/GW single-line system

for all slurry tankers and trailers

RDS rotary feedthrough for drilled BPW axles

- Tested and approved by BPW

- Patented solution for agricultural axles from BPW Rotating union bolted with grease cap – no ingress of dust and water possible

- Integrated pressure equalization element – no air ingress into the wheel hub

- Optimum protection of axle beam and axle bearing against corrosion

- High air permeability

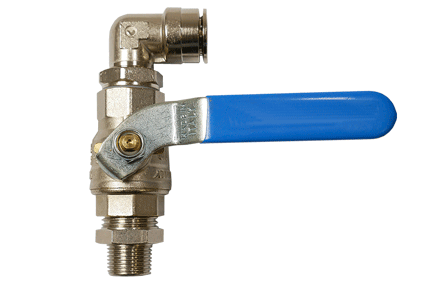

Manually operated ball valve as protection against pressure loss in the tire. Must always be closed when the vehicle is parked!

- Operation of the system via pneumatic control

- Precision control in the pressure range 0 to 4 bar (factory setting)

- No external pipes and air ducting through the pre-drilled trailer axle

- Can be combined with various PTG air supply systems

RDS rotary feed-through for drilled ADR axes

- Tested and approved by ADR

- Patented solution for agricultural axles from ADR Rotary feedthrough bolted with grease cap – no ingress of dust and water possible

- Integrated pressure equalization element – no air ingress into the wheel hub

- Optimum protection of axle beam and axle bearing against corrosion

- High air permeability

PTG universal rotary union

For drilled trailer axles such as FAD, Colaert Essieux, etc.

Dual-line system

for slurry tankers and trailers with unbored axles

AIRBOX/drive dual-line system

for all slurry tankers and trailers

- Safety against pressure loss in the tire thanks to automatically switching PTG 2L speed wheel valve

- Control line opens wheel valve only for tire pressure adjustment/measurement

- Depressurized lines when the tire pressure control system is inactive or switched off

- Maintenance-free

- Operation of the system via digital or ISOBUS control

- Precision control in the pressure range 1 to 4 bar (factory setting, 0.8 to 6 bar on request)

- Patented retaining bracket for external rotating union

- Flexible cable on the wheel for reduced risk of damage

- Cables can be uncoupled without tools

- Long service life of the rotating unions

- Can be combined with various PTG air supply systems

-

PTG Reifendruckregelsysteme GmbH

Habichtweg 9

41468 Neuss

Germany - +49 - (0) 21 31 - 5 23 76 - 0

- ptg@ptg.info